What We Do

Blastrite is a family-owned and managed manufacturer and distributor of granular abrasives. To this end, we have two mineral processing facilities in South Africa as well as sales and distribution infrastructures in Cape Town, Durban, Richard’s Bay and Johannesburg as well as distributors in Pretoria and Port Elizabeth all of which supply the shipping, construction, mining industries.

Blastrite is also a well-known name internationally with distributors of its products in North and South America; Europe; West and East Africa; the Middle East and North Africa; South East Asia; and Australasia.

Beyond abrasives materials, Blastrite enjoys agency and distribution agreements with class leading sandblasting and painting equipment producers, including:

- PanBlast™, abrasive blasting equipment

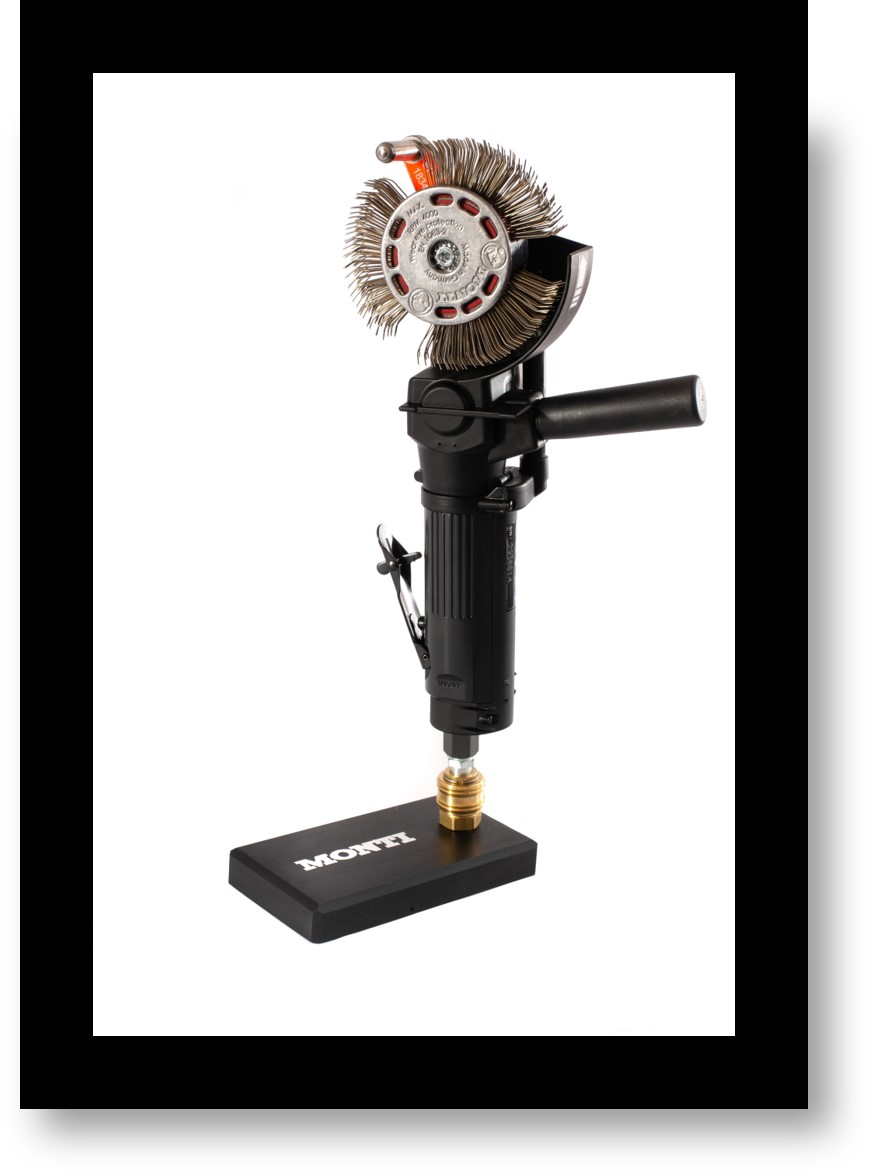

- Monti-Werkzeuge GmbH, Bristle Blaster and other mechanical preparation tools

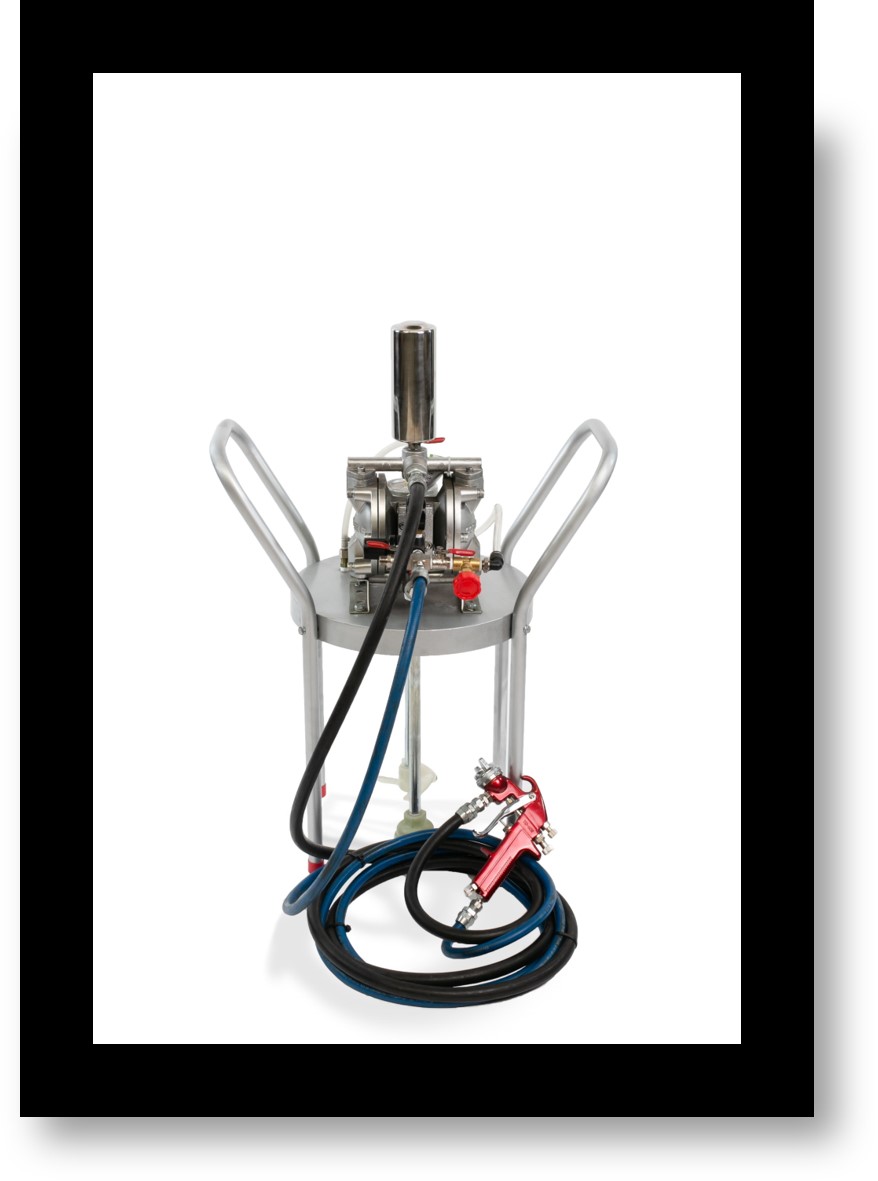

- Cosmostar, conventional and airless spray-painting equipment

- RPB Safety, personal protection equipment

- OMI, compressed air aftercoolers

About us

Blastrite is a market leader in the abrasives and surface preparation market regarding:

- granular abrasives

- and blasting and painting equipment

Blastrite has become firmly established over the past 39 years as a technical partner to the industry through ownership of resources and strategic distribution agreements with global technology leaders.

The company’s roots are in abrasive media production. Blastrite has two mineral processing facilities, one which produces industrial garnet known as Microblast®, and the other which produces our world leading Blastrite® Platinum Grit.

Our Purpose

To create value for all stakeholders through our experience, expertise and excellence.

Our Values

Attention to Service

Commitment to Quality

Trust through Value

Our products include…

Blasting abrasives

Blastrite is the market leader in the South African market with regards to the production and supply of granular abrasives to the surface preparation industry. With our roots in abrasive media production, Blastrite manufacturers Blastrite® Platinum Grit and Microblast® Garnet and also imports a range of abrasives for various applications such as aluminium oxide, glass beads, road marking beads, steel grit and steel shot.

Abrasive Blasting Systems

Blastrite’s multi-layout, High Flow blast pots boast a unique bolt-on, bolt-off leg design as well as features that enhance performance and efficiencies while blasting. Available in remote or manual configuration, these blast pots are available in 70L, 100L and 200L sizes. All accessories such as blast hose, nozzles, etc as well as spares are available from Blastrite. Also available is alternative blasting systems such as the Clemco Power Injection gun, as well as unique and economical wet blasting solutions. Blastite offers recertification of our blast pots and services and repairs on our equipment.

Conventional & Airless Painting Systems

Blastrite is the official distributor for Cosmostar, a global leader in painting systems. The airless spray range offers various ratio pumps to suit any job, while the Double Diaphragm pump is a step up from paint pressure pots to offer an easy solution for air spray applications. A large range of accessories are available off the shelf, such as the XTR7 gun and tips from Graco, 500 bar airless hoses and other spares and accessories for both airless and air spray applications. Blastrite offers services and repairs on our equipment.

Personal Protection Equipment

Representing RPB Safety, global respiratory protection specialists, Blastrite offers a wide range of PPE, including blast helmets, spray helmets, the OBE Radex breathing air filter. We also supply quality blast suits and other PPE items. Spares are available for our equipment. Safety is always a number one priority.

Mechanical Preparation Tools

Blastrite offers the patented technology of the Bristle Blaster® from Germany-based MontiPower, the only hand held power tool that can achieve an SA 3 white metal finish as well as achieving a profile on steel. The Bristle Blaster is available in both electric and pneumatic and additional belts and accessories are available off the shelf. We also offer services and repairs to the units.

Air Preparation Systems

The new integrated Aftercooler – Model 424 ensures dry air while blasting to prevent flash rust from moisture on the surface. The 424 Aftercooler also ensures blast pots remain free from clogging. This ensures continuous blasting and increased performance.

Testing Equipment

Elcometer testing equipment is known throughout the world for quality and accuracy and is available at Blastrite.

Our Locations

CAPE TOWN WAREHOUSE

Martin Hammerschlag Way,

Foreshore, Culemborg,

Cape Town

ALRODE ALBERTON WAREHOUSE

8 Johnson Street,

Alrode,

Alberton,

Gauteng

DURBAN WAREHOUSE

Unit No 4, Chelsea Industrial Park,

No 17 Chelsea Avenue,

New Germany,

Pinetown, Durban